Tact switch originated in Japan, generally by the DOME shrapnel or the industry generally with travel to distinguish, more than a certain travel is called key switch, travel is relatively small called Tact switch. Tact switches are widely used in electronics, home appliances, automobiles, military, medical, robotics, industrial automation and other fields.

When it comes to the history of the Tact switch, it is inevitable to divide it into generations, from large to small in size. Life from short to super long (thousand class, ten thousand class, one hundred thousand class, one million class); Material processes range from simple to complex (phosphor copper, stainless steel, polymer materials, laser technology, nanotechnology).

First generation tact switch

The mainstream size is 12*12mm, 8*8mm, the dimensional tolerance is plus or minus 0.1mm, the life span is 3000-8000 times, and there are more than 30000 times after improvement, so far it has a history of more than 30 years.

Second generation tact switch

The main dimension is 6*6mm, 4.5*4.5mm, the dimension tolerance is plus or minus 0.1mm, the life is 3000-50000, the improved model can reach 50000 times.

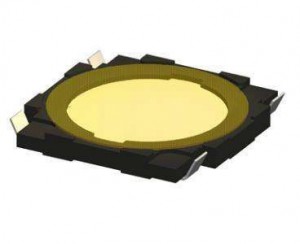

Third generation tact switch

With the rapid development of science and technology, more and more small devices enter our lives, tact switches begin to develop in the direction of smaller volume and more compact structure. Representative size of the third generation switch: 3*6, 2*4 and so on. The general life is more than 50000 times, the scope and number of applications are more extensive, you can see that this generation of switches mainly to SMT patch class development.

Fourth generation tact switch

Starting from this generation, tact switches have developed to be light and thin, and are more widely used in 3C products. Compared with the height of the previous two generations of switch products, which often exceed 10mm, the mainstream height of the third generation is controlled at about 2mm, representing products of 4*4*1.6mm and 3*6*2.5mm.

Fifth generation tact switch

The rise of smartphones, cameras, Bluetooth headsets, and home medical devices has led to increased demand for tact switches. Higher life, waterproof, stability; Extreme ultra-thin requirements have been raised, automation production, laser packaging technology, nanotechnology, polymer film materials become the production process of tact switches. It can be said that the fifth generation of tact switch is a qualitative leap, but also put forward higher requirements for raw materials, production process, quality control, automation technology. Representative switch: classic series 3*2*0.6mm, 2.8*1.9*0.6mm, 2.6*1.6*0.55mm, you can see that the height is all controlled within 1 mm, the life is as long as more than 500,000 times, the waterproof grade part has reached IP68.

Post time: May-25-2021