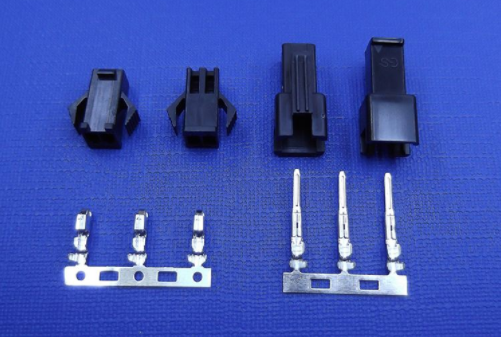

As you all know, connectors are made up of plastic cases and terminals. What is the process of making plastic cases, terminals, and then assembling them into connectors? This article will introduce the manufacturing process of the connector.

1, stamping

The manufacturing process of electronic connectors usually begins with stamping pins. Electronic connectors (pins) are stamped from thin metal strips by large, high-speed presses. One end of a large roll of metal belt is fed into the front end of the punch machine, and the other end is wound into the roll belt wheel through the hydraulic table of the punch machine, and the roll belt wheel pulls out the metal belt and rolls out the finished product.

2, electroplating

The connector pin should be sent to electroplating section after stamping. At this stage, the connector’s electronic contact surface is coated with various metal coatings.

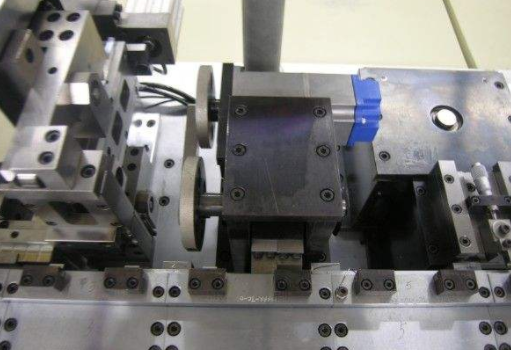

The plastic box holder for the electronic connector is made at the injection molding stage. The usual process involves injecting molten plastic into metal membranes, which are then quickly cooled to form. A so-called “leak” occurs when the molten plastic does not fill the membranes completely. This is a typical defect that needs to be tested during injection molding. Other defects include filling or partial blockage of the jack (which must be kept clean and unblocked for proper insertion of the pin during final assembly). The machine vision system used for quality inspection after injection molding is relatively simple because the backlight can easily identify box seat leaks and plug plugs.

4, the assembly

The final stage of electronic connector manufacturing is finished assembly. There are two ways to connect and plug the electroplated pins with the injection box seat: single plug or combined plug. Separate insertion refers to each insertion of a pin; The combination of a plurality of pins at the same time with the box seat. Regardless of the insertion method, the manufacturer requires that all pins be tested at the assembly stage for leaks and correct positioning; Another kind of routine inspection task is related to the measurement of the spacing on the mating surface of the connector.

The above is the production process of the connector, although there are hundreds of thousands of connector models so many, but the production of the connector is roughly such a step.

The above is the production process of the connector, although there are hundreds of thousands of connector models so many, but the production of the connector is roughly such a step.

Post time: Feb-12-2022